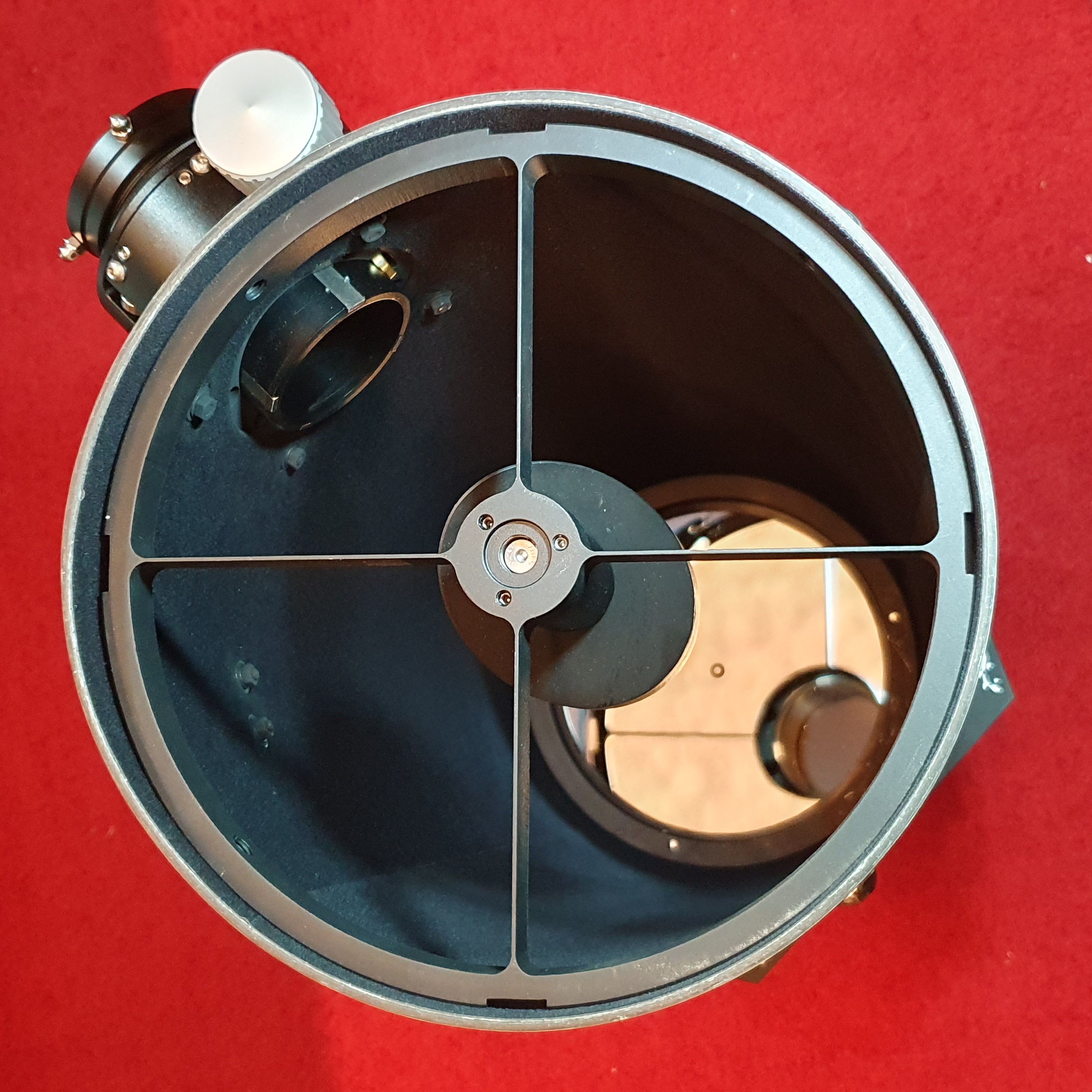

FN2008c-new

200/800 Lacerta Carbon Photonewton (assembled in Austria, Carbontube made in Hungary)

Our optimized Newtonian combines high-end features with economical design where it is possible without compromise. We have created our own brand, which is used by the most active and best photographers - because the optical quality and reliable stability are well known.

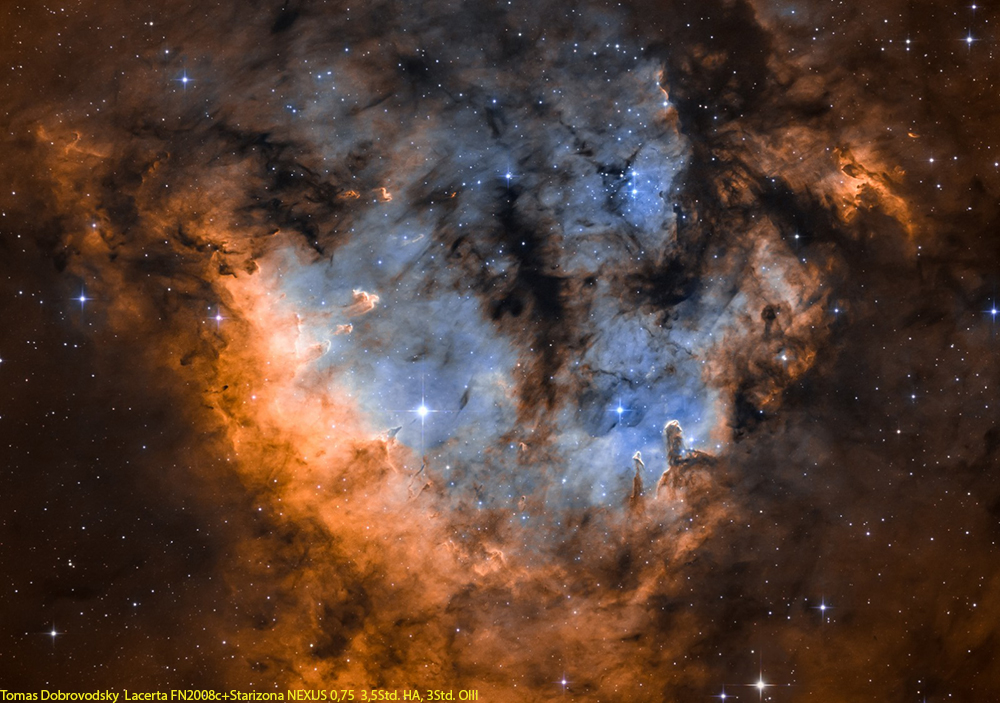

Pictures say more than words: Who takes pictures with Lacerta Fotonewtons?

Michael Jäger

Markus Blauensteiner

Jens Zippel

Herbert Walter

Rochus Hess

Michael Schmidt

Tommy Nawratil

Peter Kohlmann

The LACERTA photonewtons do not come ina box from the Far East, but are assembled from components (which mainly come from Austria, Hungary, China, Japan and Taiwan) by our workshop master Peter Kohlmann in Austria. He is ultimately responsible for the precise fit of all parts, the adjustment of the OctoPlus focuser and the stable assembly. Each specimen is fine-tuned and the optical quality is tested with an artificial star at a distance of 40 meters. The tests are evaluated together with our optics expert Tommy Nawratil, and the optics are then released or exchanged.

Not all carbon tubes are the same. To reliably produce stiffness and lightness of the tubes, special knowhow is required. Our manufacturer also produces aircraft and rocket components and has absolutely convinced us with its new quality. The carbon tubes are 6mm thick and have a honeycomb/bridge structure inside: stability increased and still weight saved! The tubes are painted white to radiate little heat upwards at night and absorb it from below.

A completely new design by Christopher Teppan and Peter Kohlmann, well thought out and optimized with Finite Elements and Plop , including several years of sacrificial testing under the Namibian starry sky! The most important features:

Most precisely positioned 9-point support for the primary mirror (one is amazed at the differences in primary mirror deformation that can result from the positioning of these 9 points!)

Elimination of optical disturbances caused by holding clamps by a full metal CNC ring aperture (not a cheap 3D printer part with a fuzzy edge, which is offered by many "experts" again and again),

possibility to adjust the distance between main and secondary mirror individually (in case you want to change the focus position for other accessories)

adjustable fit of the main mirror, no wobbling around or deformation due to pressure

complete absorption of forces and focus shift by swinging from zenith to horizon,

...and much more...

A focuser with maximum stability, already in its 3rd generation with oversized bearings, designed and built by Peter Kohlmann.

The coma corrector is kept stable on axis by the slip fit in the focuser tube, but is fully rotatable. The centerlock clamp, designed by G. Perger (Hungary) and further developed by us, holds it securely in position, even with an eccentric filter wheel and with several kg of load (up to 4kg already tried).

When we say "stable", it does not mean "a tick more stable than other extractors", but REALLY stable. We have tested the lateral bending forces and minimized deviations, and the results speak for themselves. The OctoPlus focuser is prepared for a LACERTA MFOC motor focus with 1 micron reproducible focusing accuracy and with optional temperature sensor.

Customer quote (Rochus Hess): "The focuser is indeed very stable and the corrector fits exactly into the focuser, you did not promise too much".

Customer quote (Bernd Weinzierl): "Tommy I really like this part!!! Perfect clamping, no tilting, no shifting, how could I get along without the Octo???"

In fact, the absorption coefficient for grazing incident light is even better than with velour. At the same time, the foil acts as an additional insulating buffer layer for heat exchange between the tube wall and the inner air, and further reduces the already low tube entrance due to the white carbon tube. The film is so densely flocked that it looks like velor at first glance - but unlike velor, it does not absorb moisture or lose fibers.

If blackening is to be done, then do it properly! Stray light can also come from the lighter side surface of the secondary mirror. Blackening the rough secondary mirror side surface effectively prevents this!

The adjustment screws of the secondary mirror are designed as Allen screws, so that you can create good tension during adjustment. This is important so that the fan mirror remains nailed in position even when panning. A steel washer prevents the screw tips from digging into the mirror holder, which often leads to adjustment problems with cheap solutions.

We offer to install mirror heaters at the same time. The supply lines are laid as flat cables along the spider legs, so that they do not protrude. An RCA connector is placed in the tube wall.

Too thin secondary mirror struts warp and bend too easily, and are usually screwed individually to the tube. Therefore you have to take care that they are well aligned during adjustment to avoid unsightly fanned out spikes. The new end ring, including spider legs and FS retaining block, is now cut from a single aluminum block with a laser beam and reworked with CNC. The deformation behavior between the telescope tilted towards the horizon and zenith was computer modeled to keep the secondary spiders as thin as possible, but at the same time to suppress the deformations. The spider legs thus align perfectly and neither yield nor can they be mistakenly adjusted. The end ring also serves as the end stiffener for the carbon tube, and optimally stabilizes the nearby OctoPlus extension.

The hexagonal tube clamps are also full of ideas. They allow rails to be attached at the bottom, top, and another 4 positions (fully compatible with the LACERTA BAUKASTEN system). There are several M6 threads at the top and bottom, and they can be re-drilled at the side.

A minor detail, but you may appreciate it: There is nothing sticking out of the Lacerta pipe clamp (not even the clamping screws) where a cable could get caught during nighttime operation. Unless you want it to: there are plenty of pre-drilled holes with M6 threads if you want to attach accessories or strain relieve cables....

The LACERTA photonewton has a backfocus of 55mm above the centerlock or GPU coma corrector, but can be configured to be versatile. It is also fully usable visually. For this purpose, the coma corrector can be equipped with an eyepiece sleeve (M48nM54p508). For visual observation without a coma corrector, take an extension under the eyepiece adapter (2x M48M4837). For observation with binoviewer, the coma-correcting Düring Barlow is suitable as a glass path corrector ( APM267x ), or the Baader 1.6x coma-correcting glass path corrector. Photographically, the focal length can also be extended, either with comacorrecting Barlows like the APM16x , or with normal Barlow lenses.

If the focus position should ever not fit, a 12mm sleeve can be removed from the OctoPlus extension ( Octo60plus12mm ) and you can focus further in. You can also screw on more 12mm sleeves to get further out. The OctoPlus also holds a corrector on axis when its not on - its no problem to use the corrector as a continuously adjustable sleeve and re-clamp it. This is just a suggestion to try it out for yourself and discover possibilities!

Customer quote (Michael Jäger): "I have had the Newton in my car for 25,000km and have never had to readjust it."

Customer quote (Norbert Mrozek): "You have really built a great instrument, I am totally thrilled. I was able to take the first pictures yesterday evening. Everything you promise, you deliver."

We offer to this f/4 photonewton as a package offer also the 4-lens GPU Komakorrektor: KomakorrF4 (optical Design by Pal Gyulai / GPU / Hungary). Unlike simpler correctors, it does not cause spherical aberration on the optical axis. To see the difference between the 4-lens GPU and probably the best dual-lens coma corrector (MPCC by Baader), you should open both images below in two separate windows and then compare them. Note the fine planetary nebula at the center of the image and the limiting size (courtesy ONLY for Teleskop-Austria of Burkhard K. from Bondorf - copyright please note!)

www.teleskop-austria.at/info...4-lens-GYULAI.jpg

www.teleskop-austria.at/info...-2-lens-MPCC.jpg

Weight: 11kg (with tube rings and Losmandy rail)

Overall length: 790mm

Diameter tube 245mm (outside)

tube thickness: 6mm

secondary 70mm small axis

secondary 535mm above HS

focal point 140mm above tube/70mm above OAZ

Mirror material: Pyrex, total system has no temperature drift all night long

Tube clamps, Losmandy rail, finder bracket, front and rear covers

Our

photonewtons are best adjusted before optics test, then well packed on

wooden pallets and delivered by a professional shipping company such as

Dachser.

This is a bit more expensive than a normal parcel service, but the safest and smoothest transport method.

Self-collection in one of our branches is welcome and of course free of charge!

M45 (Rochus Hess mit FN2008c-flat und Gemini G53f)

Iris Nebula by Stefan Roth

hier finden Sie einige optische Testberichte